How's hydraulic shock phenomena happen?

2025-05-22

Hydraulic Shock, also known as the water hammer effect, is a common phenomenon in fluid power systems, especially in hydraulic systems and pipeline networks. When a fluid suddenly stops or changes its flow direction, due to the effect of inertia, the fluid will generate pressure waves. These pressure waves can propagate within the system and may cause damage to it.

The causes of hydraulic shock

Quickly close the valve: If the valve or other control components close rapidly, preventing the flow of the liquid, the part of the liquid before the closing point will continue to move forward due to inertia, thus forming a high-pressure area.

Sudden start or stop of the pump: When a hydraulic pump suddenly starts or stops working, it can also cause a similar impact phenomenon.

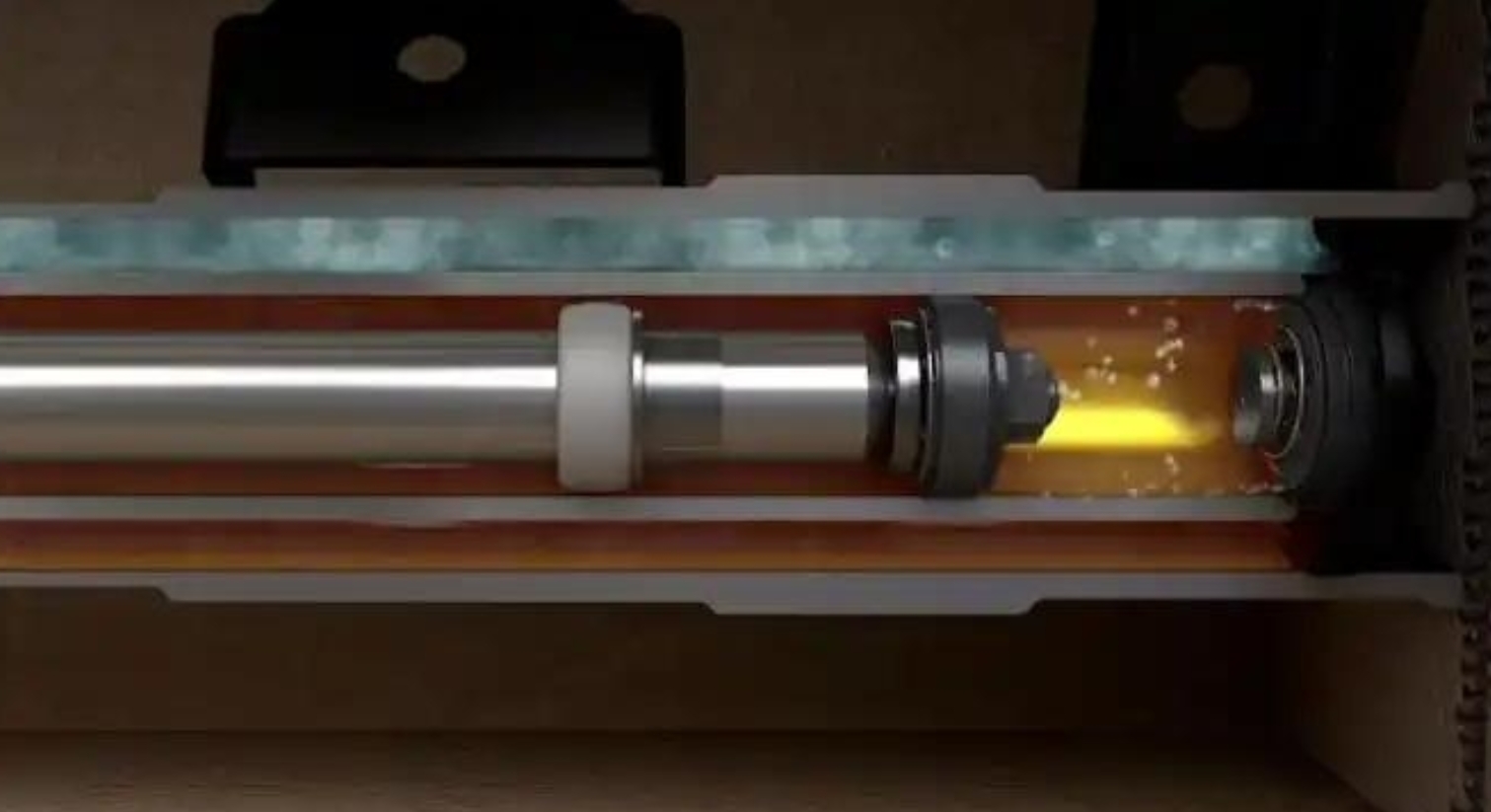

Sudden start or stop of the pump: When a hydraulic pump suddenly starts or stops working, it can also cause a similar impact phenomenon. - the piston movement: in some of the hydraulic cylinder, if the piston move rapidly to the limit position, may cause the liquid is compressed, causing shock.

Damage

Sudden start or stop of the pump: When a hydraulic pump suddenly starts or stops working, it can also cause a similar impact phenomenon. - the piston movement: in some of the hydraulic cylinder, if the piston move rapidly to the limit position, may cause the liquid is compressed, causing shock.

Performance degradation: Frequent hydraulic shocks can affect the system's response speed and stability, reducing work efficiency.

Reduction method

Use buffer devices: Install accumulators or buffers to absorb excess kinetic energy and reduce the impact of shock.

Optimize the control system: Adopt a progressive opening and closing method, such as achieving smooth regulation through proportional valves or servo valves, to avoid sudden actions.

Increasing the pipe diameter or shortening the pipeline length: Appropriately increasing the pipe diameter can help reduce the flow velocity, while reducing the pipeline length can lower the time and intensity of shock wave propagation.

Select appropriate materials and designs: Use materials with strong pressure resistance and sufficient flexibility to manufacture pipes and fittings; Plan the system layout reasonably to disperse potential pressure points.

In conclusion, the phenomenon of hydraulic shock is a matter that requires attention in hydraulic systems. We need to conduct regular inspections to minimize damage to the equipment.