What are the mounting types of hydraulic cylinder?

2025-05-20

As an important actuator in the hydraulic system, the hydraulic cylinder realizes the reciprocating motion of the machinery by converting hydraulic energy into mechanical energy. It is powerful and operates smoothly, and thus has been widely applied in many industries such as construction machinery, agriculture, and automobile manufacturing. For hydraulic cylinders, how to install them is very important. If they are not installed properly, it will lead to misalignment, excessive wear, and even system failure. Therefore, choosing the correct mounting type can help avoid the above problems and ensure the smooth operation of the hydraulic cylinder.

Hydraulic cylinders can be mounted by using clevis, trunnion , foot mount, flange mount, etc. Each mounting type has its own distinct features and applicability. Next, we will specifically discuss these common mounting type for hydraulic cylinders.

Clevis

The clevis is a "U" -shaped mount welded to the end of the barrel or rod. It achieves the suspension and fixation of the hydraulic cylinder through the U-shaped structure, allowing the hydraulic cylinder to swing freely within a certain angle range to adapt to different working requirements. Clevis mount are usually used in movable machinery and allows for limited rotational motion.

Trunnion

The trunnion is composed of pins located on both sides of the hydraulic cylinder barrel and is used to support the hydraulic cylinders in the assembly. The trunnion mount can be integrated with most rod mounting types. It enables the hydraulic cylinder to pivot radially within a plane, facilitating smooth rotational movement. It provides greater flexibility.

Flange

A flange is a component that tightly connects a hydraulic cylinder with other mechanical equipment or pipelines through the combination of flange plates, bolts, gaskets and other parts. The flange is fastened with high-strength bolts to ensure the reliability of the connection. It features high connection strength and excellent sealing performance, making it suitable for large-scale hydraulic systems, especially excelling in high-pressure and heavy-load environments.

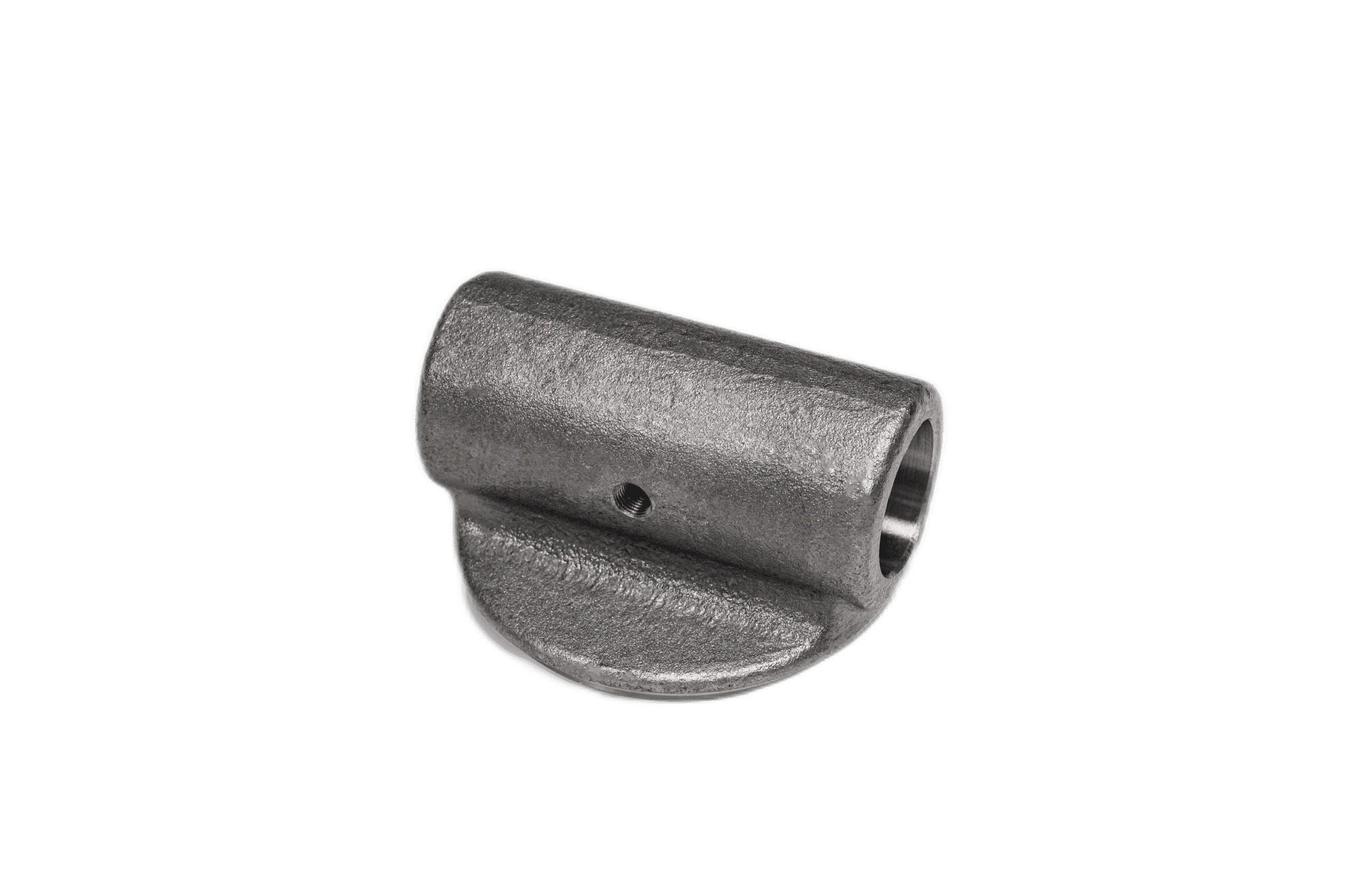

Cross tube

The cross tube is a tube welded across the end of the barrel or rod, it can connecting the hydraulic cylinder with other hydraulic components or equipment to form a stable hydraulic system. The design of the cross tube makes the entire system structure more compact, saves space, and can withstand forces from multiple directions at the same time, making it suitable for complex working environments.

Choosing the most suitable mounting type for hydraulic cylinders requires consideration from multiple aspects, such as application type, load direction, installation space, etc. In practical applications, the appropriate mounting type should be selected based on specific application conditions. TOLENG is a professional manufacturer of hydraulic cylinders with over 20 years of experience. We are willing to join hands with you to choose the most suitable hydraulic solution for your equipment.