What should be noted when disassembling a hydraulic cylinder?

2025-06-30

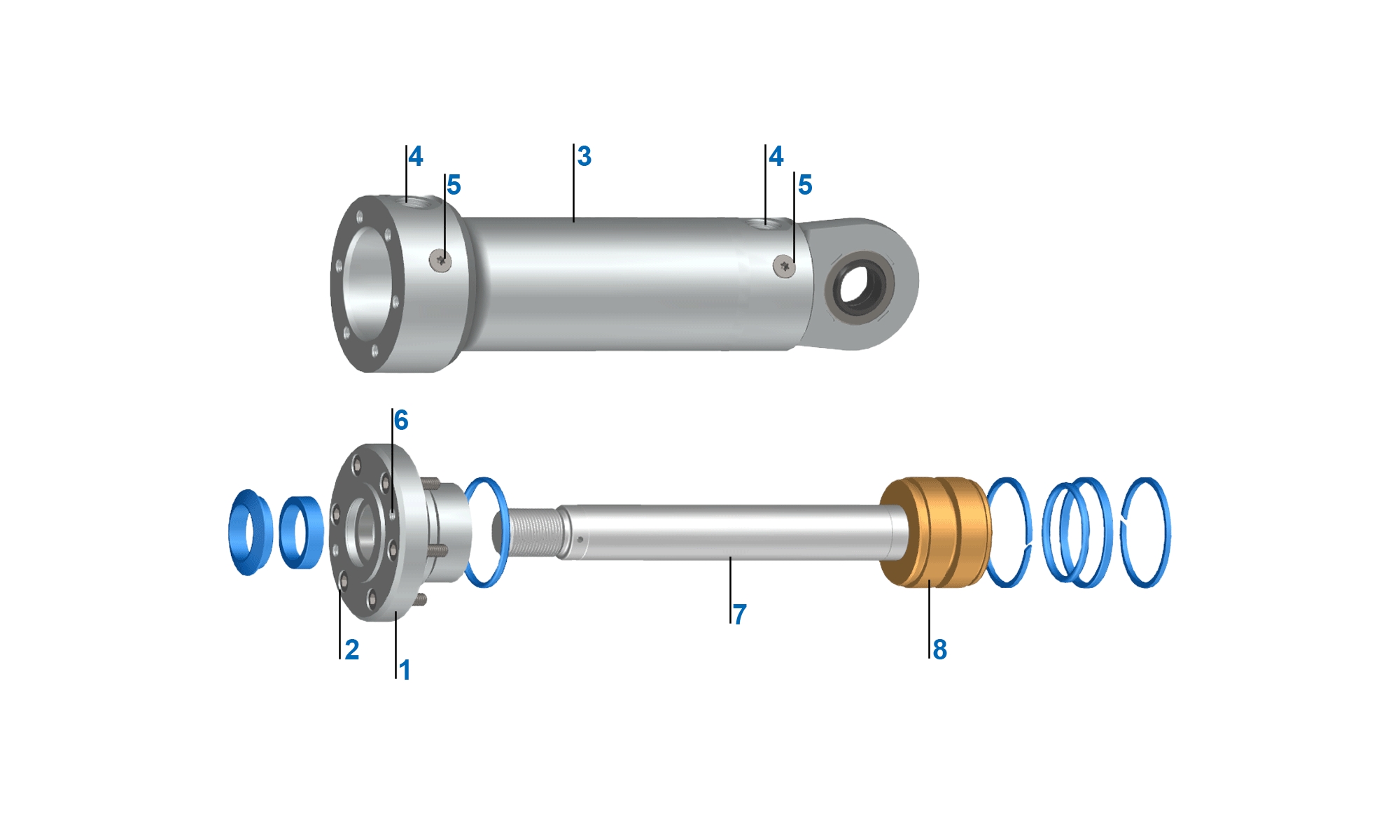

You might think that repairing a hydraulic cylinder is a piece of cake. But without the right tools and expertise, it will soon turn into a nightmare. When your hydraulic cylinder malfunctions, you need to repair it quickly and accurately at the first moment, as they are crucial to your productivity. If one component of a hydraulic cylinder malfunctions, it usually affects the performance of other components. Therefore, all maintenance of hydraulic cylinders requires a complete disassembly and reassembly of the cylinder body. During the disassembly process, it is necessary to thoroughly inspect the wear and tear and signs of failure of each component. So, what should be noted during the disassembly process?

1. Preparations for disassembly

Before disassembling the hydraulic cylinder, it is necessary to ensure that the pressure in the hydraulic circuit has been released. Subsequently, the power supply or power source should be cut off to completely stop the operation of the device. This concerns the safety of the dismantling workers. Therefore, these preparations are indispensable.

2. Disassembly sequence

When disassembling a hydraulic cylinder, a certain sequence must be followed. Generally, when disassembling a hydraulic cylinder, we need to first drain the hydraulic oil from both chambers of the cylinder, then remove the cylinder head, and finally take off the piston and piston rod. When disassembling the cylinder head, special tools are needed. If the piston and piston rod cannot be pulled out, the cause should be carefully identified first before proceeding with the disassembly operation.

3. Cleaning

To prevent the parts of the hydraulic cylinder from being contaminated during the disassembly process, the disassembly operation should be carried out in a clean environment as much as possible. Meanwhile, all parts should be covered with plastic sheeting, and cotton cloth or other working cloths should not be used to cover them to avoid the parts being contaminated with lint.

4. Inspection

All the disassembled parts of the hydraulic cylinder must be inspected. For hydraulic cylinders with after-sales problems, especially careful inspection is needed. Through inspection, it can be determined which parts can continue to be used, which parts need to be repaired before reuse, and which parts must be replaced.

In conclusion, the disassembly process of the hydraulic cylinder is an indispensable step for its maintenance. This is a task that requires meticulous operation and strict standardization. Ensuring the safety and accuracy of each step is of vital importance. Through standardized disassembly methods, the maintenance efficiency can be improved, the service life of the hydraulic cylinder can be prolonged, and the stable operation of the hydraulic cylinder can be ensured.