Can hydraulic cylinders be used in high-temperature environments?

2025-05-12

Hydraulic cylinders are important actuating components in hydraulic systems. The application of hydraulic cylinders in high-temperature environments is a complex issue. Whether they can operate normally in high-temperature conditions requires comprehensive consideration from multiple aspects such as design, materials, and sealing, and also depends on the high-temperature resistance performance of each of their components. The following will conduct a detailed analysis of the applicability of hydraulic cylinders in high-temperature environments from multiple perspectives.

The basic structure and working principle of hydraulic cylinders

As the actuating element in the hydraulic system, the hydraulic cylinder is mainly composed of the cylinder barrel, piston, piston rod, sealing parts, end cover and other components. Its working principle is that the pressure of hydraulic oil drives the piston to move in a straight line in the cylinder barrel, thereby converting hydraulic energy into mechanical energy.

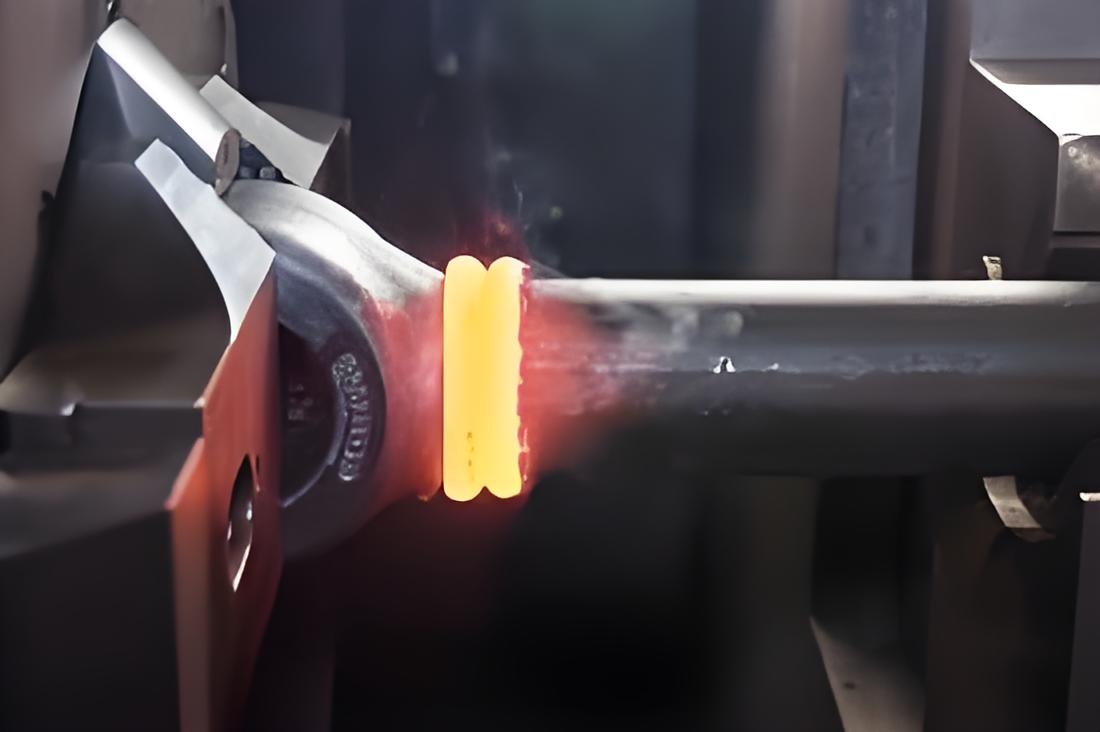

The impact of a high-temperature environment on hydraulic cylinders

High-temperature environments can have varying degrees of impact on the various components of hydraulic cylinders, mainly reflected in the following aspects:

The decline of material properties

The main components of a hydraulic cylinder, usually the cylinder tube and piston rod, are made of metal materials, like carbon steel, stainless steel, and aluminum alloy. In a high-temperature environment, the mechanical properties of metallic materials will change.

Sealing failure

Seals are crucial components in hydraulic cylinders, whose function is to prevent hydraulic oil leakage and the entry of external contaminants. Common sealing materials include rubber, polyurethane, fluororubber, etc. In high-temperature environments, sealing materials are prone to aging, hardening, deformation and even decomposition, leading to a decline in sealing performance and subsequently causing leakage problems. The failure of seals not only affects the working efficiency of hydraulic cylinders but may also lead to faults in the hydraulic system.

Hydraulic fluid performance variation

Hydraulic fluid is the working medium in a hydraulic system, and its performance directly affects the working effect of the hydraulic cylinder. In high-temperature environments, the viscosity of hydraulic oil will decrease, leading to a decline in lubrication performance and an increase in friction and wear. In addition, high temperatures will accelerate the oxidation of hydraulic oil, generating acidic substances and sediment, which can contaminate the hydraulic system and affect the normal operation of hydraulic cylinders.

Whether a hydraulic cylinder can be used in high-temperature environments depends on its comprehensive performance in multiple aspects such as materials, seals, hydraulic oil and design.

By choosing high-temperature resistant materials, optimizing the sealing design, selecting high-temperature hydraulic oil, and enhancing cooling and heat dissipation, the hydraulic cylinder can operate normally in high-temperature environments. However, high-temperature environments still have a certain impact on the performance and service life of hydraulic cylinders. Therefore, in design and application, high-temperature factors need to be fully considered to ensure the reliability and safety of hydraulic cylinders. TOLENG is an experienced hydraulic cylinder manufacturer, we will offer you excellent service and professional technical guide , please contact us at sales01@phtl.cn