How to inspect a hydraulic cylinder?

2025-05-04

Hydraulic cylinders can convert hydraulic energy into mechanical energy and are important actuating components in many industries, agriculture, construction and forestry. Due to long-term use, these hydraulic cylinders cannot always be in the best working condition. In some cases, even minor faults can cause damage to the hydraulic cylinders. Therefore, it is very important to inspect the hydraulic cylinders for the equipment. The inspection of hydraulic cylinders mainly includes the following aspects:

Appearance inspection

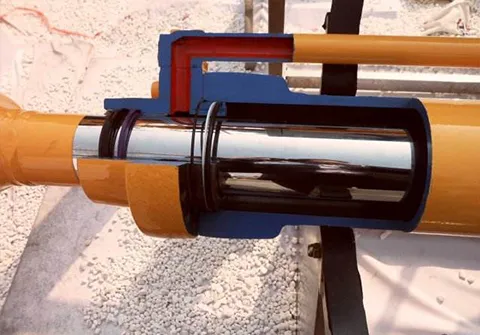

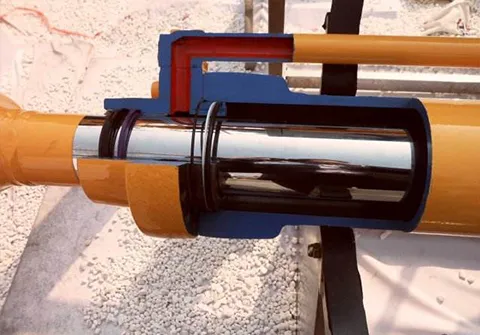

First, check whether there are obvious cracks, wear, or corrosion marks on the surface of the cylinder barrel. Surface damage is the easiest to detect.

Check whether the seals are intact and whether there is any damage or aging. The seals are the key components to ensure that the hydraulic cylinder does not leak.

Check whether the piston rod has scratches or deformations that affect the working efficiency of the hydraulic cylinder.

Leakage inspection

Leakage is also a relatively serious fault for hydraulic cylinders, so it is necessary to conduct regular leakage detection on hydraulic cylinders.

External leakage inspection: Observe whether there is any hydraulic oil seeping out from the outside of the cylinder, especially at the extension end of the piston rod, the oil pipe joint and the connection of the cylinder body.

Internal leakage inspection: Determine whether the internal seal is good by measuring the leakage amount of the hydraulic cylinder under different pressures.

Dimensional and precision inspection

Dimensional and precision inspection

Correct dimensions and installation can ensure the smooth operation of the hydraulic cylinder on the equipment.

Check the stroke length: Measure the actual stroke of the hydraulic cylinder to ensure it meets the design requirements.

Check the installation dimensions: Inspect the installation dimensions of the hydraulic cylinder to ensure correct installation and use.

Inspections in other aspects

Inspections in other aspects

Check the hydraulic oil: Inspect whether the hydraulic oil level in the oil tank is normal and whether the hydraulic oil needs to be replaced.

Temperature: Monitor the temperature changes of the hydraulic cylinder during operation. Abnormally elevated temperatures may indicate poor sealing or excessive friction.

Noise: Under constant pressure, check for any abnormal noise or vibration.

Through the above inspection, the working condition of the hydraulic cylinder can be evaluated, which helps us identify problems with the hydraulic cylinder as soon as possible and solve them in a timely manner. If your equipment needs to be replaced or you need professional knowledge about hydraulic cylinders, please feel free to contact us.