What aspects should be noted when disassembling a hydraulic cylinder?

2025-04-29

The disassembly of hydraulic cylinders is a process that requires careful operation, involving multiple steps and precautions. To ensure the safety and efficiency of the disassembly process, it is necessary to follow the correct steps. The following is the specific process.

First, it is necessary to cool down sufficiently

During operation, the hydraulic cylinder will generate high temperatures. Before disassembling the hydraulic cylinder, after stopping the running equipment, it is necessary to wait for the hydraulic cylinder to cool down sufficiently. If disassembly is carried out too early, it may cause safety hazards.

Second, the hydraulic cylinder needs to be cleaned.

Before disassembling the hydraulic cylinder, clean the dirt on the surface of the hydraulic cylinder thoroughly to prevent it from entering the interior and affecting its use. Meanwhile, ensure that the working area is clean and tidy. This is not only beneficial for maintaining the hygiene of the machine, but also can reduce the interference of oil dust.

Third, the pressure of the hydraulic circuit should also be relieved.

If the pressure of the hydraulic cylinder is not relieved, when the oil pipe joint connected to the cylinder is loosened, the high-pressure oil in the circuit will spray out rapidly. When releasing pressure in the hydraulic circuit, first loosen the handwheel or pressure regulating screw at the relief valve and other places to release the pressure oil, then cut off the power supply or the power source to stop the operation of the hydraulic device.

Wear and tear should also be noted when disassembling.

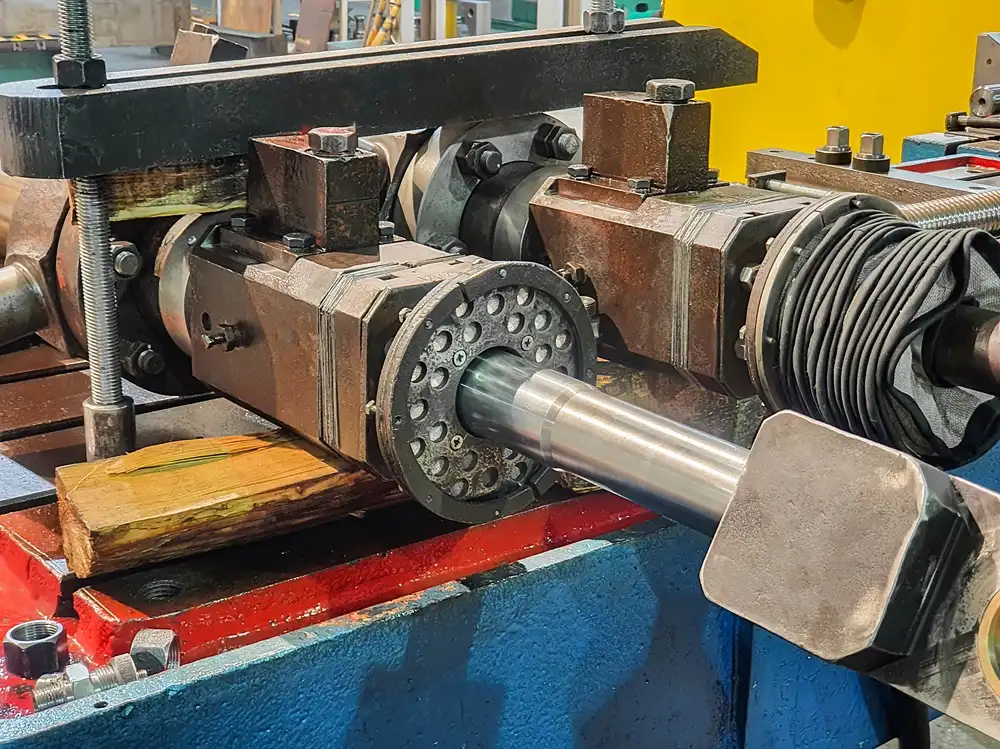

When disassembling, care should be taken to prevent damage to the top thread of the piston rod, the oil port thread, the surface of the piston rod, the inner wall of the cylinder liner, etc. To prevent the piston rods and other slender parts from bending or deforming, they should be placed supported evenly with wooden blocks.

Finally, after disassembly, a thorough inspection should be conducted to determine which parts can continue to be used, which can be reused after repair, and which must be replaced.